High Level Palletizer VPEKS Automation Faster Case Palletizing Bag Stacking Machine in Henan, China

New

Doubleclick to zoom in

Contact the seller for

additional photos and information.

Specifications

- Condition

- new

- Application

- Food Beverage Commodity Chemical Machinery & Hardware APPAREL

- Packaging type

- Cartons CANS Bottles Barrel Stand-up Pouch Bags Film Foil case

- Packaging material

- Plastic paper metal Glass

- Automatic grade

- Automatic

- Driven type

- Electric

- Voltage

- 380v/220v

- Place of origin

- Henan

- Dimension(l*w*h)

- 3100*2000*2800mm

- Key selling points

- High Productivity

- Machinery test report

- Provided

- Video outgoing-inspection

- Provided

- Core components

- motor PLC Pressure vessel Engine

- Model name

- VPK-GWPT High Level Palletizer

- Packing speed

- 800 to 1200bags per hour

- Weight per bag

- 5kg to 50kg per bag

- Working type

- push type

- Included item 1

- Feeding conveyor

- Included item 2

- PLC cabinets

- Applicable industries

- hotels Garment Shops Building Material Manufacturing Plant Machinery Repair Food & Beverage Factory Farms Home Use Construction works Energy Mining

- Warranty of core components

- 1 Year

- Weight

- 3200 KG

- Power

- 13kw

- Category

- Palletizers in China

- Subcategory

- Packaging line

- Subcategory 2

- Packaging machines

- Subcategory 3

- Industrial machinery

- Listing ID

- 101436716

Description

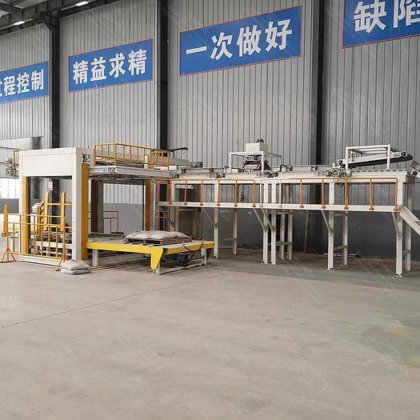

Fast Speed high level case infeed palletizer bag palletizing machine upper level

made by VPEKS Automation

High-level palletizer

High level infeed conventional palletizers are generally faster and have a comparatively smaller footprint than floor level palletizers. Additionally, more efficient traffic flow can be realized in plants when there are multiple palletizers in one area or the palletizing process is located a significant distance from the packaging area.

How a high-level palletizer is made and how it works

The machine is composed of a rigid high-level case palletizerwith a vertical frame sliding on it and this holds the pallet being formed. The full bags coming from the filling line are raised to an orienting device.

Following the programmed palletizing pattern, the bags are initially arranged on the row-formation roller conveyor and then when a row is composed, it is shifted to a temporary parking area.

Find more

$13,000 USD