Bottling Line - 2009 in Fumane, Veneto, Italy

Used

Doubleclick to zoom in

Contact the seller for

additional photos and information.

Specifications

Description

Machine type Manufacturer Model Year Notes

Depalletizer italproject MAXIPAL300 2009

Capper FMT MS 250+AV 600 2008

Sterilizer FMT ST 2008 Tilting Conveyor - Sterilizer

Bottle Cooler FMT Bottle Cooler

Dryer 2 Matrix Dryer 2 2009

Labeler CLEVER MACHINES GS 301 2009 Sleeve

Various Equipment CLEVER MACHINES Tunnel Steam STJ 2 2009

Wrap Around Packer PENTATEC WA90 M 2009

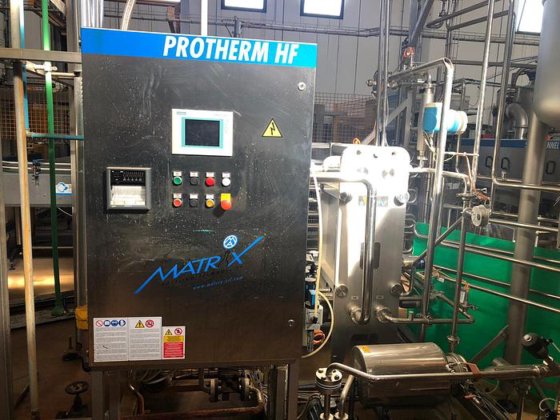

CIP System Matrix Proclean 3R2 (CIP) 2009

Inspector Heuft Level - Caps

bottling system for sale Hot filling system for Glass up to 10.000 bph

Hot filling system composed of:

Top cover with laminar flow

Fake bottles set

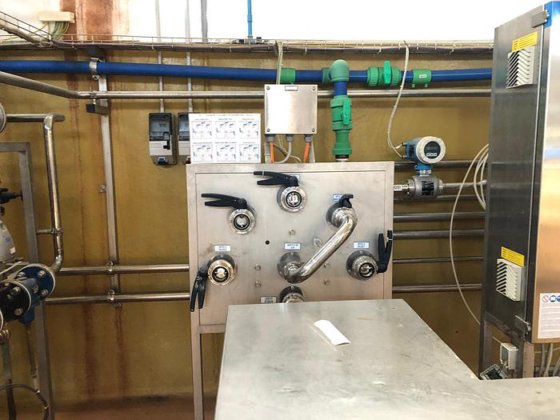

Hot Fill recirculation system

Supplement for parts in contact with product in Aisi 316

N.1 cylindrical bottle format change

Bottle conveyor belt systems

Packet conveyor systems

Electrical panel for tapes management

Heuft Control System

Syrup room

Year of realization 2009

Products:

a) Fruit juices

b) Nectars

Type of filling:

Hot filling system

Formats:

a) 0,25 liters (glass)

b) 0.50 liters (glass)

c) 1.00 liters (glass)

Semi-automatic juice preparation unit for Hot filling system:

a) Nr. 1 drum emptying station with pneumatic pump and mass flow meter for:

– fruit juices or purees

– liquid sugar

b) automatic water dosing unit with magnetic flow meter

c) Nr. 2 tanks of 200 liters for dissolving and emulsifying powders and aromas previously weighed (manual loading)

d) N.1 tank with 8,000 lt agitators (SUPPLIED BY THE CUSTOMER)

e) Nr. 1 transfer pump

f) No. 1 homogenizer of 4,000 lt \ h

f) 2 tanks with 15,000 lt agitators (predisposition for the future insertion of 1 other 10,000 lt tank)

g) positive transfer pump for feeding to the flash pasteurizer

h) 1 pump per washing phase

i) parts in contact with product in AISI 304

I) Electric control panel

bottling system for sale OPTIONALS:

Parts in contact with product in AISI 316

Capping:

Twist Off diam. 38 mm

Labeling:

Wrapper sleever full body

Juices production:

• 10.000 bp / h (0,250 En)

• 5.000 bp / h (0,500 En)

• 2.500 bp / h (1,000 It)

Liquor production:

• 1.500 bp/h (0,250 lt)

• 750 bp/h (0,500 lt)

Packaging:

WRAP AROUND cartons (6×4 on 0,25 and 2×3 on 1 It)

1.A BOTTLING ROOM

a) Semi-automatic push-on depalletizer with ground blade

b) bottles preheating steam tunnel, length 2 meters

c) automatic triblock mod. tecna hf-v hot fill 24/24/6 pitch 125.6 (prepared to add capping turret and capper outlet star).

Triblock manufacturer: Matrix,

Filling head manufacturer: Arol

d) bottle size change set: (N. 2 format changes available)

e) Twist off linear capper for 12,000 bph with electronic synchronization with filler

f) high speed magnetic caps elevator with automatic waste control system

g) 15 sqm cooling tunnel with 30 min cycle on 10.000 bph diam 60 mm base (external dimensions 3×9 mt)

h) 2-module bottle drying tunnel

i) automatic labeling machine for sleeves complete with steam tunnel, motorized belt and output ejector (label thickness 50 micron)

j) ink jet coder

k) bottle conveyor system as per layout (annex_1)

l) 10 ppm wrapper packaging machine

m) electrical control panel for bottle and parcel tapes (preliminary) complete with cables and channel placed above the tapes.

2.B PASTEURIZER FLASH 2500 LT / H

In AISI 304L and with parts in contact with product in AISI316 mounted on skid complete with degaser, with APV plates and without Homogenizer.

Composed by:

– transfer pump managed by Inverter

– degaser station

– N.1 preheating station from 2 to 50 ° C

– N.1 heating station from 45 to 95 ° C heating stage from 45 ° C to 95 ° C (using hot water)

– N.1 pre-cooling station from 95 to 85 ° C

– N.1 cooling station from 80 to 40 ° C with glicoLate water

– hot water preparation

This line can be modified to work with PET bottles

Services offered by seller

This seller offers new machines

This Seller offers repair & maintenance services

This seller offers spare parts

This seller offers transport & logistics

This Seller offers consultancy services

This seller can help you plan & execute entire projects

This seller offers on-site assembly and disassembly